There are lots of different cables available on the market, each suited to a specific range of applications. Finding the right one for your particular needs can be overwhelming. Understanding the specific aspects that should influence your purchasing decision can help to narrow your focus and determine the appropriate cable for your needs.

There are lots of different cables available on the market, each suited to a specific range of applications. Finding the right one for your particular needs can be overwhelming. Understanding the specific aspects that should influence your purchasing decision can help to narrow your focus and determine the appropriate cable for your needs.

Important factors to consider include:

- Cable use

- Environment

- Temperature

- Flexibility

- Standards

- Specs/drawings

- Budget

Knowing the particulars of your application needs in these seven areas can help you communicate effectively with a cable and wiring expert.

Information You Need

When you call or email a cable and wiring expert to find the best product for your project, having specific information at the ready will expedite the process. Before you call or start shopping, gather any requirements you have for the following areas:

Cable Use

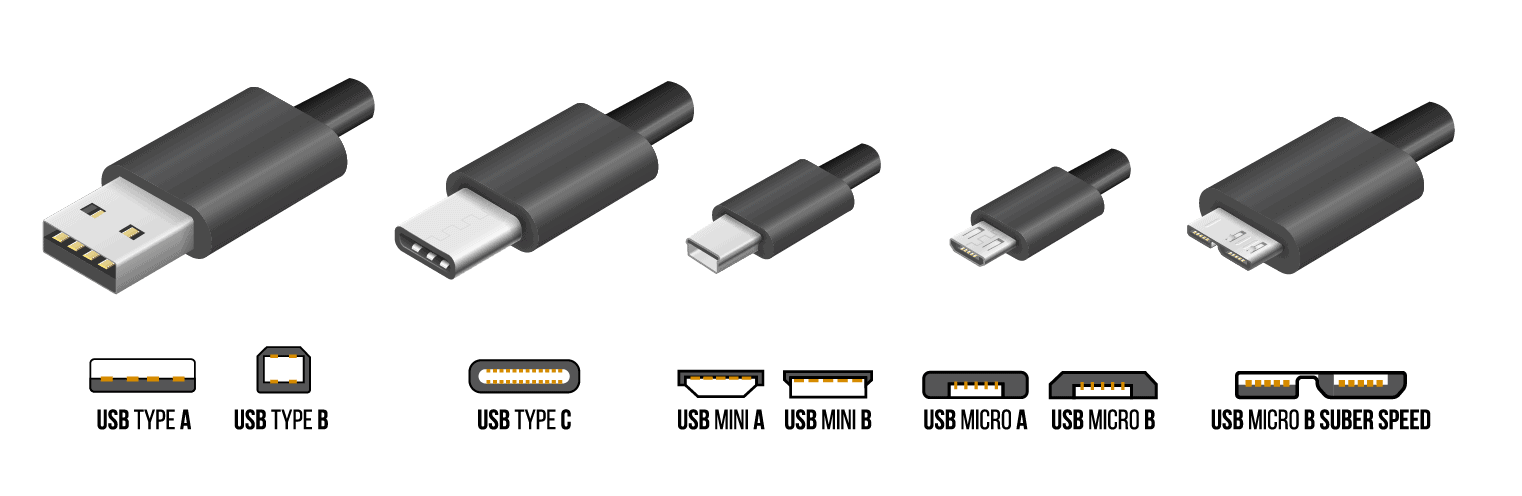

Cables have between one and 100 different connectors depending on their intended purpose. If you know how the cable will be used in the future, your service provider can better determine which combinations and gauges to include, as well as what materials to use.

Environment

The environment in which the cable will handle its primary functions is one of the most important factors. The metal composition of the wire has to be able to withstand the environment, or else it will lose long-term effectiveness. For example, if you expect the cable to have a lot of outdoor usages, your service provider may recommend tinned copper wire, which can resist corrosion and oxidation. If your new cable will be used in hot environments, silver-plated copper is a better choice. Having this information from the outset ensures you get the cable you need faster.

Beyond just the choice of metal material, different cables have varying layers of exterior protection. The non-metal tubing that protects the wires or wire groups—called the jacketing—plays an important role in keeping the environment away from the wires. For weather-resistant cables, carbon blank may be combined with PVC, semi-rigid PVC, or PE jacketing. If the area is home to a lot of extreme weather, the jacketing might have polypropylene, polytetrafluoroethylene, or polyurethane layers instead.

Temperature

Insulation gives wires the ability to withstand greater temperature extremes in both indoor and outdoor applications. With the right materials, manufacturers can insulate wires to keep them safe for use in environments with a temperature as low as -65° C or as high as 250° C. Insulation can also protect against non-temperature factors such as moisture and air pressure. All cables, regardless of application, must be insulated against atmospheric conditions.

Flexibility

Wires that are moved frequently throughout the day need a great deal of flexibility so they don’t break or wear through. You can request cabling in these three different flexibility designations: normal, flexible, and robotic-flexible. The wiring itself plays a role in flexibility by either using thick, solid strand wires with low gauges (which would be very rigid) or multiple thinner strands (which are more flexible).

Different jackets can impede or allow overall flexibility. Polyurethane is an excellent jacketing choice because it provides both strength and flexibility. If cables should be completely rigid instead, manufacturers can make them from solid conductors.

Standards

Every cable should also meet the applicable industry and safety standards. Some standards you should take note of include:

- ISO 9001 (International Organization for Standardization)

- RoHS (Restriction of Hazardous Substances)

- CE Mark

- NEC (National Electrical Code)

- UL (Underwriters Laboratories)

- CSA (Compliance, Safety, Accountability)

- OSHA (Occupational Safety and Health Administration)

- VDE Association for Electrical, Electronic and Information Technologies

- LF (Lead Free)

- Mil-Spec (Military Specifications & Standards)

Specs/Drawings

Manufacturers can meet specific needs if they’re given detailed drawings. If you need to recreate a previously existing cable or have a cable rebuilt to meet more exacting standards, your wire and cabling manufacturing company can let you know about their capabilities and if they can perform the task before the project begins. They need as much detailed information as possible to make that determination. They can also address previously existing deficiencies in older cables.

Budget

Knowing your budget before placing an order or consulting with a cable manufacturing expert can help them find the right materials and processes. They can make sure you get the best possible performance within your budget.

Consolidated Electronic Wire & Cable Solutions

Consolidated Electronic Wire & Cable is a leading manufacturing company in the wiring and cabling industry and we have been developing custom cables for over 100 years. Call us today for expert assistance in finding the right materials, jacketing, and design considerations for your project.

() Quote Cart

() Quote Cart

Comments are closed