Private labeling involves the manufacturing of a product or item by one company for another, after which the second company sells the product under its name or brand. Many large corporations rely on private labeling if they don’t have an in-house manufacturer for a certain part or product. As a result, they can ensure that their components are manufactured correctly and cost-effectively while staying true to their brand.

The advantage of private labeling is that a company can obtain an essential component for a low cost without having to add additional facilities or staff. It also gives the company greater control over production and branding, since it has the ability to make changes whenever necessary. Most importantly, by using a manufacturer who specializes in a particular field or area, companies can be sure that they’re receiving the highest-quality product available, which in turn increases the quality of their overall product, device, or system.

Private Solutions with Public Benefits

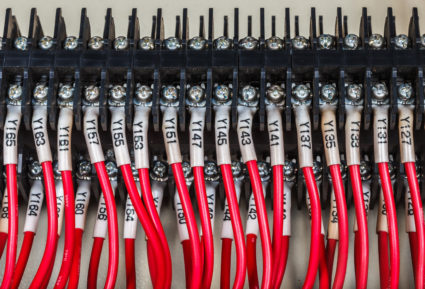

While private labeling has taken off in numerous industries, it’s become particularly popular among industries and companies that depend on cables and other electronic devices. Many of Consolidated Wire’s clients, for example, are communications companies that need specialized cables for their products or internal infrastructure.

By closely collaborating with a manufacturer, a company can develop a cable tailored to its specific needs without spending the large sums needed to hire and train an in-house manufacturing team.

In recent years, Consolidated Wire did just that by helping a client in communications develop customized manufacturing retractile cords with custom DIN connectors. When the customer came to us with specific requirements, our team reviewed its specifications and then used precision over molding to craft the cables. Using custom tooling over the mold, we then manufactured the DIN connector with strain relief and used polypropylene as the base material.

This collaboration resulted in lasting solutions to pressing challenges. After performing full quality control procedures to test its functionality and performance, our team provided the client with a custom 12-inch retractable cord that can extend to a full 60 inches. Today, we manufacture thousands of these custom cords for the company in only a few weeks.

Counting on Consolidated Wire

For more than 100 years, Consolidated Wire has provided custom cable solutions for clients in every major industry. Backed by our well-honed expertise in cable building and state-of-the-art facilities, we’re able to create custom cables for any customer who might need cables but doesn’t have the manpower or facilities to manufacture them independently. With the continued rise of private labeling, we are ready to supply any company with specialized solutions to their manufacturing challenges.

As leaders in private labeling, we pride ourselves on our versatility. Offering a wide array of building materials, we’re able to modify the flexibility, insulation, jacketing, and sheathing of our products according to your needs. In addition, we can fill everything from small orders of a few hundred cables to large bulk orders. Regardless of your field, we have the experience and resources needed to identify an ideal solution for your business.

With our wide-ranging capabilities and sterling reputation within the industry, Consolidated Wire can meet almost any specification for any application. If you’re interested in learning more, contact us today to begin creating your own private label cable.

() Quote Cart

() Quote Cart

Comments are closed