Cable Assembly 101: What It Is, Types, & Applications

Comments Off on Cable Assembly 101: What It Is, Types, & ApplicationsAlso known as wiring looms or cable harnesses, cable assemblies keep individual cables well organized to simplify their use, installation, and maintenance in electrical applications. Vital to electrical systems, machinery, and other electronic devices, numerous types of cable assemblies are available to fulfill varied needs, based on the unique requirements of your application. Learn more about these assemblies, the many types available, and their common applications.

What Is a Cable Assembly?

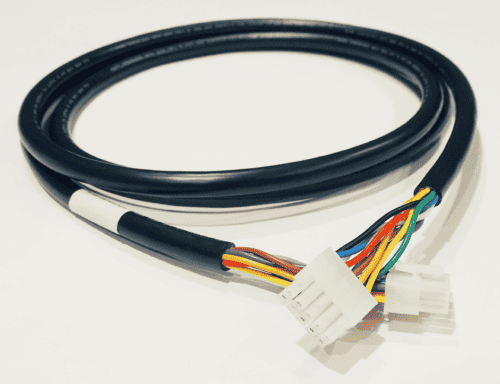

Cable assemblies are made up of several cables grouped together in a single bundle with the help of cable ties, tapes, or sleeves. Such bundles may consist of multiple types of cables and are available in different dimensions, lengths, and colors. The end result is an organized, structured, and durable cable assembly that saves space, facilitates installation and maintenance, and ultimately protects the integrity of the individual cables. These rigid assemblies effectively transmit signals and provide power for various applications and are typically suitable for use outdoors.

Types of Cable Assemblies

You can choose from many different types of cable assemblies to meet your needs, with the following factors influencing the optimal assembly for your specific application:

- Necessary cable length

- Transmitted signal type, such as data, control, or power

- Requirements surrounding electrical current and voltage

- Temperature range, chemical exposure, vibration levels, and other environmental factors

- Connector type or termination you require

Of the cable assemblies available on the market, the most common options are:

- Coaxial cable assemblies. Possessing the recognizable F-type connector, coaxial cables are highly flexible and durable, with the ability to transmit electrical signals for Wi-Fi, TV, and similar applications.

- Molded cable assemblies. The connectors and wires in these assemblies form a single component encompassed in injection-molded plastic. This encapsulation boosts these assemblies’ flexural strength and resistance to strain.

- USB cable assemblies. Available in different types and speeds, highly versatile Universal Serial Bus (USB) cable assemblies are a popular choice for charging applications and high-speed data transmissions.

- D-sub cable assemblies. Telecommunications and computing projects may use D-sub cable assemblies, which feature D-shaped metal shielding and multiple rows containing female sockets or male pins at each connection.

- LED cable assemblies. In everything from automotive and commercial applications to residential and decorative lighting, these assemblies comprise low-voltage LED cables for energy-efficient lighting systems.

- Ribbon cable assemblies. Ribbon cables form flat, ribbon-shaped assemblies consisting of wires arranged in a parallel format, offering mass termination capabilities as well as enhanced ease of use and maintenance for compact spaces.

- Circular connector cable assemblies. As the name suggests, these durable connectors have a circular pattern, transmitting power or data using a secure connection that’s resistant to EMI, vibration, and environmental factors.

Cable Assemblies vs. Wire Harnesses

An alternative to a cable assembly is a wire harness. While these terms are often used interchangeably, they are two separate product options. The main differences between them are their construction and their durability. Generally, cable assemblies join multiple cables together using a sleeve or jacket, giving the appearance of a single — albeit thick — wire. Their more rigid structure offers stress resistance and makes them capable of withstanding wear or outdoor environmental conditions.

The sheath in wire harnesses, however, covers each individual wire or cable, and they are simply grouped together within the harness. Each separate wire or cable is visible, facilitating separation as needed. The less durable of the two, wire harnesses are better for indoor applications. They also are not the optimal choice for compact spaces.

Whichever option you choose, going with a custom solution will deliver greater application flexibility and allow you to tailor your assembly or harness to your specific requirements.

() Quote Cart

() Quote Cart